As fabric makers, artistry, free creative expression, and sustainability are at the heart of our DNA.

For over three decades we have applied sustainability criteria both to our fabrication and choice of materials, to minimize our impact and contribute positively to climate change.

Today, we aim to engage with customers and consumers by providing a rational mindset on sustainability, defining all actions and initiatives that Crevin is carrying out at as weaving and finishing mill, under the title Road to Zero.

Shifting the paradigm to sustainability in textiles

Our Road to Zero is our ambitious journey towards zero-impact in textiles, built around zero-waste, zero-water, and zero-CO2.

We strive for progress seeking collaborations across the industry, engaging our team, suppliers, customers, and end-users to ensure full transparency and relevance, while providing a platform for the interactive sharing of information, concerns, and experiences.

Our Road to Zero is made measurable by providing Life Cycle Assessment (LCA) data on all our fabrics. LCA data assess our CO2 and water footprint annually, enabling the reduction of our impact while providing sustainability performance information to customers and end-users.

If you have questions about Crevin’s sustainability initiatives or need product-specific sustainability information, use this contact form.

Sustainability by Design

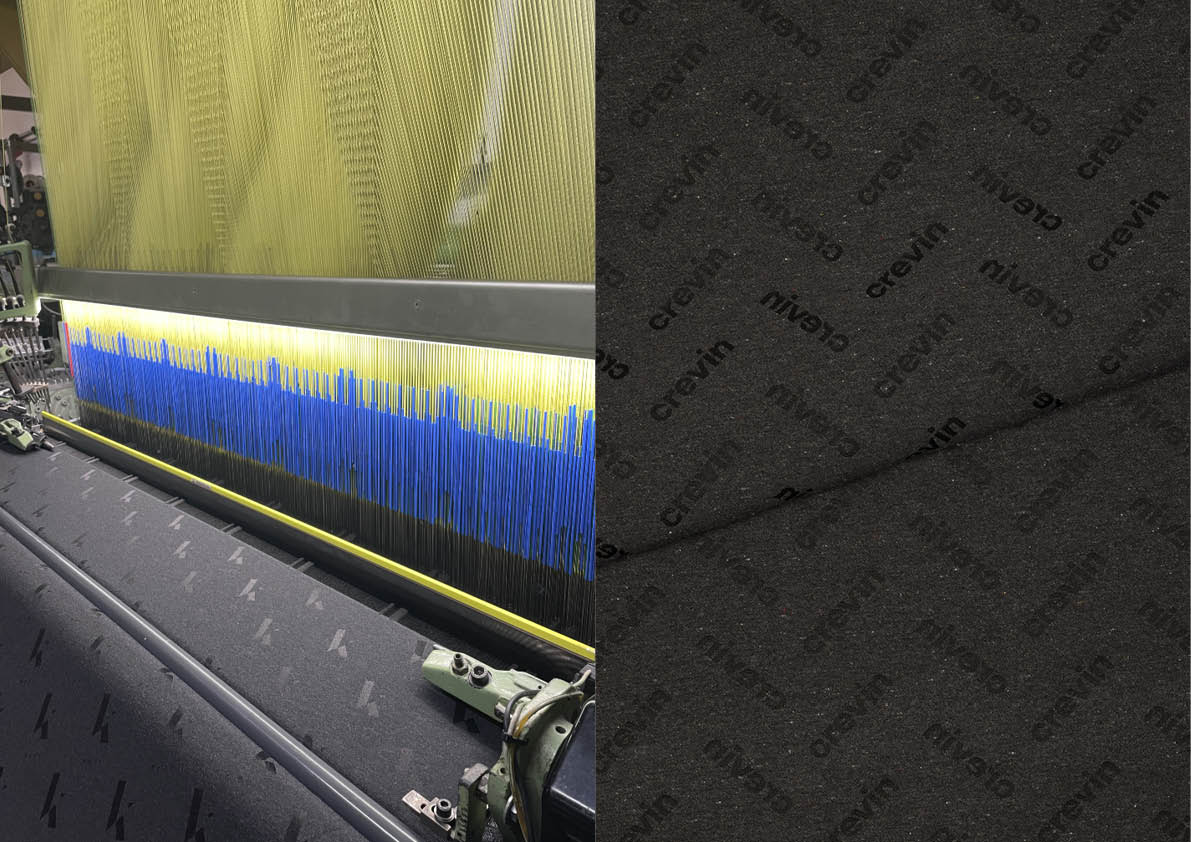

Sustainable design is the driving force of our Road to Zero. Our design philosophy considers the materials, production and lifecycle of our fabrics. We create with the purpose to give our products the longest and most useful life possible. Longevity is optimized by constructing our fabrics in two interwoven layers, which enables us to apply recycled materials to our entire product range. Our production is waste-free and driven by energy from renewable sources. We source high-quality, low-impact and GRS-certified materials from local partners to guarantee quality and service while reducing transport and CO2 emissions.

For over three decades we have applied sustainability criteria both to our fabrication and choice of materials, to minimize our impact and contribute positively to climate change.

Today, we aim to engage with customers and consumers by providing a rational mindset on sustainability, defining all actions and initiatives that Crevin is carrying out at as weaving and finishing mill, under the title Road to Zero.

Shifting the paradigm to sustainability in textiles

Our Road to Zero is our ambitious journey towards zero-impact in textiles, built around zero-waste, zero-water, and zero-CO2.

We strive for progress seeking collaborations across the industry, engaging our team, suppliers, customers, and end-users to ensure full transparency and relevance, while providing a platform for the interactive sharing of information, concerns, and experiences.

Our Road to Zero is made measurable by providing Life Cycle Assessment (LCA) data on all our fabrics. LCA data assess our CO2 and water footprint annually, enabling the reduction of our impact while providing sustainability performance information to customers and end-users.

If you have questions about Crevin’s sustainability initiatives or need product-specific sustainability information, use this contact form.

Sustainability by Design

Sustainable design is the driving force of our Road to Zero. Our design philosophy considers the materials, production and lifecycle of our fabrics. We create with the purpose to give our products the longest and most useful life possible. Longevity is optimized by constructing our fabrics in two interwoven layers, which enables us to apply recycled materials to our entire product range. Our production is waste-free and driven by energy from renewable sources. We source high-quality, low-impact and GRS-certified materials from local partners to guarantee quality and service while reducing transport and CO2 emissions.

Zero-Waste

1. Reutilization of textile waste through circular recycling

Every year our mill generates tons of manufacturing waste in the form of selvedge offcuts, yarn ends and cutting straps. We collect and sort all this waste and send it to a local spinner that turns it into yarn for us.

How is our waste recycled back to fabric?

Crevin fabrics are double-woven. In double-weaving two warps (vertical yarn) are employed instead of one, forming a durable, double-layered quality. Recycled materials, like the yarn made from our own waste, are woven into the backside of new fabric.

Our achievements

• All back-weaves of Crevin fabrics are made from 100% recycled material.

• Every year, more than 70,000 kg of textile waste is saved from landfill or incineration.

2. Recycling of textile waste into lining fabric

Since 2023, we offer customers a recycled lining fabric* that is made from our textile waste and recycled polyester. This recycled lining fabric is personalized with our customer’s logo.

*In upholstery, a lining is used to cover the filling of the cushions and the underside of sofas.

Our achievements

• The recycled lining fabric offers customers an effective tool to engage end-users in sustainability in textiles.

• Since July 2023, we have produced over 20.000 meters of recycled lining fabric.

3. Upcycling of stock leftovers in new products

In 2022 we set up a platform offering our cuttings and stock leftovers to micro and small enterprises to support local artistry and NGO’s that strive for job opportunities for people at risk of social inclusion.

Achievements

• Today Crevin caters to NGO’s and local artisans covering miscellaneous products and services.

Zero-Water

Recycling of wastewater through ultrafiltration

In 2022 we installed an ultrafiltration station to filter and

reuse the water used during our dyeing and finishing processes.

Achievements

• We reuse the 70% of our wastewater, saving around 100.000 liters of freshwater every day.

• Vertical ultrafiltration membranes filter out microplastics that pollute the aquatic environment.

Zero-CO2

100% electricity from renewable sources

Since September 2022, our mill is exclusively powered by green energy generated mainly by windmills.

Achievements

• 27.200 kg of CO2 is non-emitted every year.

• This is the equivalent of 899.181 km (more than 22 times the earth’s perimeter) travelled in a 2022 Ford Fiesta.

Certifications

Our journey is made tangible to consumers by providing relevant certifications from accredited certifying bodies.